€26.45 (no TAX)

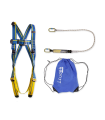

Anti-fall system with light plus 5 harness Irudek Mont Blanc

Anti-fall system with light plus 5 harness Irudek Mont Blanc von absorbed from antistatic rope

Unit/ box: 10

€85.75 (no TAX)

Anti-fall system with light plus 5 harness Irudek Mont Blanc, 1 absorber semistatic cord ref. 361 and 2 muskets Steelsafe ref. 981:

The light plus 5 harness is made of 44 mm polyester.

This kit has been designed for easy, fast and safe use. They're anti-fall systems, so they're certified to absorb the impact of a fall.Fall harnesses are personal protective equipment (PPE) against falls from a height and comply with EN 361:2002. The anti-roll harness is a basic component of the anti-roll system according to EN 363:2018. Some harnesses are fitted with a positioning belt (EN 358: 1999), may also incorporate a seat harness (EN 813: 2008) for use in restraint, retention or rope access systems or may incorporate escape anchorages for life-saving (EN 1497: 2007). IRUDEK harnesses comply with EU Regulation 2016/425 on PPE.

CHARACTERISTICS

COMPONENTS:

- 1 light harness plus 5:

- Textile back anchorage + textile lining (A/2)

- Extension tape

- Adjustable on legs

- 1 semi-static cord absorber ref. 361:

- Energy absorber with semi-static cord. Designed to withstand falls.

- Reduces impact from falls below 6kN

- Rope ends sewn and covered with polyethylene material, abrasion resistant guardrails.

- Two steelsafe muskets ref. Other: Steel connector with screw-type manual closure.

- 1 bag of net

TECHNICAL DATA OF THE LIGHT PLUS 5 HARNESS

- Weight: 1,5 kg

- Harness strength > 15kN

- Rings resistance: 22 kN

- Tape width: 44 mm

- Weight: 140 kg

LIGHT PLUS 5 HARNESS MATERIALS

Tape material: 44 mm polyester

High tenacity polyamide

Rings: Steel

Bails: Steel

SEMI-STATIC WIRE ABSORBER

- Length: 150 cm

- Weight: 45 grams

- Diameters and widths

- Static resistance: 25 kN

- Stop distance: 1m

- Shelf life (years): 10 years of use and 1 year of storage

SEMI-STATIC WIRE ABSORBER MATERIALS

Rope materials: Polyamide

Manufacture from materials of any heading

TECHNICAL DATA STEELSAFE MUSKET

- Weight: 174 kg

- Aperture: 18 mm

- Locking: Screw-Lock

- Useful life: Unlimited

STEELSAFE MATERIALS

Body made of steel

Head: steel

PACKAGING KIT

Unit/ box: 10

Packing length: 35 cm

Packing width: 17 cm

Height of packaging: 15 cm

APPLICATIONS

The use of the mooring element with an anti-rolling subsystem shall be compatible with the instructions for use of each component of the system and with the standards: EN 355, EN 361, EN 362.Indicated for work at heights, it is therefore often used in work environments such as:

- Civil works

- Construction industry

- Mountaineers

- Industry as a whole

SIZE GUIDE

Size: S, M, L, XL, XXL and 3XL

%2000-05-44.png)

%2000-03-09.png)

STANDARDS AND REGULATIONS

IN361 - Personal protective equipment against high falls. The fall harness.

IN362 - Personal protective equipment against high falls. Connectors.

IN355 - Personal protective equipment against high falls. Machinery for making pulp of fibrous cellulosic material

RESTRICTIONS ON USE

- The equipment must be individually attributed to one person. - It is recommended that the anchorage point where the anti-fall system will be fixed be above the user. The anchorage point shall have a minimum static resistance of 12 kN and shall comply with the requirements of EN 795.ATTENTION

- A fall harness is the only acceptable body restraint that can be used in a fall harness. - The fallprotection system must be connected only to the harness connection points marked with the capital letter “A”. The identification A/2 indicates that it is necessary to connect simultaneously two disconnection points with the same identification. It is prohibited to connect the protective system to a single connection point identified by A/2”. - In harnesses with a built-in belt, the positioning work equipment must be connected only to the belt's lateral anchorage rings. - Connection to the anchorage point and to other equipment must be by means of muskets in accordance with EN 362:2004. - For use with fall guard EN 353-1:2014+A1:2017, EN 353-2:2002 it is recommended to connect the equipment to the front anchorage point of the harness. For use with EN 355 energy absorbers or EN 360 anticides it is recommended to connect the harness dorsal anchorage device. - Before each use of personal protective equipment, it must be checked carefully to ensure that it is in working order and functioning properly. - During the pre-use check it is necessary to carefully inspect all equipment elements to verify that they show no signs of deterioration, excessive wear, corrosion, abrasion, degradation by UV radiation, or incorrect use. Pay particular attention to tapes, seams, anchor rings, buckles and deregulation elements.LIFETIME

The estimated service life of the equipment is 11 years from the date of manufacture (1 year of storage and 10 years of use). The following factors may reduce the shelf life of the product: heavy use, contact with chemicals, particularly harsh environments, exposure to extreme temperatures, exposure to ultraviolet rays, abrasion, cuts, heavy impacts, or poor use and maintenance. The mandatory annual review shall validate the correct operation of the equipment. The equipment must be examined by the manufacturer or an authorised person at least once a year. If a fall has been stopped, the equipment must be withdrawn from use.MAINTENANCE INSTRUCTIONS

- CLEANING: Personal protective equipment must be cleaned in such a way as not to cause adverse effects on the materials used in the manufacture of the equipment. For textile and plastic materials (tape, rope) clean with a cotton cloth or brush. Do not use any abrasive material. For deep cleaning, wash the equipment at a temperature between 30oC and 60oC using a neutral detergent. For metal parts with a damp cloth. If the equipment gets wet, either from use or from cleaning, it should be allowed to dry naturally away from direct heat.

- STORAGE: Personal protective equipment should be stored in a loose package in a dry, ventilated place, protected from sunlight, ultraviolet rays, dust, sharp-edged objects, extreme temperatures and harsh substances.

ABOUT IRUDEK

Irudek Group is an expanding group of companies with headquarters in Spain, operations in Italy, Brazil and India and sells its products in more than 50 countries. Irudek Group is safety and guarantee, backed by years of experience and by customers who have placed their trust in its products.

heading

Declaración de Conformidad 981 Cumple con los requisitos del Reglamento/ Directiva de Equipos de Protección Individual (EPI) download

Declaración de Conformidad 361 Cumple con los requisitos del Reglamento/ Directiva de Equipos de Protección Individual (EPI) download

Declaración de Conformidad Light Plus 5 Antes de cada utilización el aparato de descenso por cuerda deberá ser sometido a un control visual por elusuario download

Manual de Usuario Absorbedores Leer atentamente las instrucciones de uso antes de utilizar el absorbedor de energía download

Manual de Usuario Conectores Leer atentamente las instrucciones de uso antes de utilizar el conector download

Manual de Usuario Arneses Leer atentamente las instrucciones de uso antes de utilizar el arnés download

@CUSTOMER_NAME@

@AUTHOR_PROFILE@ @COMMENT_ISO_COUNTRY@ @VERIFY_PURCHASE@@COMMENT_TITLE@

@COMMENT_COMMENT@