HOW TO MEET YOUR OBLIGATIONS TO PROTECT WORKERS IN CONFINED SPACES

Health and safety professionals have an important role in ensuring that all necessary precautions are taken to protect workers, and this technical guide offers practical advice on how to carry out these tasks in five easy steps.

The guide not only covers the legislation that employers and safety professionals must comply with, but also explains some key non-regulatory but complementary measures that can be taken before a worker enters a confined space

Step 1: Know your legal obligations

Firstly, employers and health and safety professionals whose workers operate in confined spaces need to be aware of their legal obligations. This ensures that risks are minimized by meeting basic safety requirements. Currently, the EU does not have a single common regulation for work in confined spaces. However, there are some directives that set out minimum requirements to ensure protection against some of the risks posed by confined spaces.

Directive 89/654/EEC on workplace requirements obliges employers to ensure “that there is sufficient fresh air in enclosed workplaces, taking into account the working methods used and the physical demands placed on employees.” workers” while Directive 92/57/EEC on temporary or mobile construction works requires that:

• “6.2 In the event that some workers must enter an area whose atmosphere could contain toxic or harmful substances, or do not have sufficient oxygen or be flammable, the confined atmosphere must be controlled and appropriate measures must be taken to prevent any danger. .

• 6.3 Under no circumstances may a worker be exposed to a high-risk confined atmosphere. He must, at least, remain under permanent surveillance from the outside and all due precautions must be taken so that effective and immediate assistance can be provided.

There is also wider safety legislation in place to ensure that the property takes all necessary measures to protect workers in any environment, including confined spaces. Directive 89/391/EEC - OSH 'Macro Directive' sets out general prevention principles to protect the health and safety of workers in all aspects of their work, including requirements that are clearly relevant to confined spaces:

• Adopt “the necessary measures regarding first aid, fire fighting and evacuation of workers” and the actions required in case of serious and imminent danger.

• Take appropriate measures to ensure that “only workers who have received appropriate instructions can access areas where there is a serious and imminent danger.”

Some European countries have taken the protection of confined space workers a step further by adopting specific regional legislation.

For example, in Spain, ROYAL DECREE 604/2006 introduced the mandatory presence of preventive resources in actions to be carried out in confined spaces. According to the provisions of article 8 of the Occupational Risk Prevention Law, the National Institute of Safety and Hygiene at Work is the specialized technical scientific body of the General Administration of the State whose mission is the analysis and study of the conditions of work. safety and health at work, as well as the promotion and support for their improvement. The National Institute of Safety and Hygiene at Work establishes that in any intervention in a confined space, at least all of the following preventive measures must be adopted:

1. Measurement and risk assessment of the indoor atmosphere before entering the confined space.

2.People entering must have a continuous environmental meter, a self-rescue mask and a permanent means of communication with the outside.

3.Favorecer natural ventilation by opening all openings and ventilate mechanically by blowing air through the lower part. If necessary, clean the space from the outside.

4.Aislamiento total of the intervention area: limiting access exclusively to the people who must act and consigning the fluids and energies accessible from the outside.

5.The intervention team must be made up of at least two people, one of whom must be a preventive resource and remain permanently abroad.

6.Disponer of a rescue system (harness and lifting system) that allows action if necessary.

7. All actions must be previously authorized by the person designated to control the performance of special work and be carried out according to a previously established procedure.

Step 2: Assess the risk

As the above legislation clearly outlines, the safest option is to always avoid entering a confined space. With this in mind, it is important to evaluate whether a task can be performed correctly from outside the confined space. For example, it may be possible to clean the area using pressurized water, steam or tools with extended handles, or to remove blockages in silos using remotely operated rotating flail devices and air bleeders. However, if entry into a confined space is unavoidable, a risk assessment is an important step in protecting workers as well as complying with the law. Risks must be reduced “to the minimum reasonably practicable” and risk assessment is the first step in achieving this requirement. A risk assessment helps ensure that major risks – those with the potential to cause real harm – are considered, while minor risks are also recognised. The following factors should be considered:

• The general condition of the confined space (for example, chemical waste, contamination from an adjacent plant, gas collectors or surrounding terrain, oxygen deficiency/enrichment, dimensions and layout).

• Hazards associated with the job (e.g., cleaning chemicals that may interact with the atmosphere of the confined space, potential ignition sources such as welding, heat, or strenuous work activity may have an effect on the worker's thermal comfort).

• Hazards coming from outside (substances such as liquids, gases, steam, water, raw materials from nearby processes and services).

• Requirements for emergency rescue (for example, equipment and measures necessary for an employee rescue).

A risk assessment considers the probability that a hazard becomes an accident with respect to the consequences of that accident. Based on the results of the assessment, corrective actions are taken to reduce the risk, such as:

• Supervision

• Competence for work in confined spaces

• Communication

• Atmosphere testing/monitoring

• Atmospheric purge

• Ventilation

• Waste removal

• Isolation of gases, liquids and other floating materials (closed, labeled)

• Isolation of mechanical and electrical equipment

• Selection and use of appropriate equipment

• PPE (Personal Protective Equipment), PFPE (Personal Fall Protection Equipment) and RPE (Respiratory Protective Equipment)

• Portable gas cylinders and internal combustion engines

• Gas supplied by pipes and hoses

• Access and return

• Fire prevention

• Lights

• Static electricity

• Smoke

• Emergencies and rescue

• Limited working time

The risk assessment reference document is mandatory for all enterprises and should be reviewed annually or when the working conditions and characteristics of the enterprise change.

A five-step process is often used for risk assessments. Remember that a risk assessment is not simply a document created to keep track, it identifies what needs to change, if any, before it is safe to start working.

For continually changing hazards, such as wind speed, it is common to use a 'dynamic' risk assessment, which sets out a range of allowable conditions under which work can be carried out. Outside this range, work stops and a formal evaluation is repeated.

Depending on the risks involved, a 'work permit' procedure may also be considered. This ensures that, before a worker can enter a confined space, a formal check is carried out to confirm that all the elements of a safe work system are in place.

Step 3: Training

As mentioned above, training is a key element of a safe work system. It is also a legal obligation in the EU and, in countries such as the UK, extends to temporary contractors or self-employed individuals operating under the control and direction of the company. This is an important consideration as it is not uncommon for temporary contractors, who have not received adequate training, to perform tasks such as cleaning or maintenance in confined spaces. With this in mind, flexible and accessible learning tools help ensure that they can be trained quickly and easily to work safely in confined spaces.

The employer's obligation is to prepare user instructions and provide appropriate training. Workers are required to use the personal protective equipment provided to them, follow instructions and report any equipment failure.

Another important consideration when it comes to confined space training is technology. For example, virtual reality (VR) operations simulators provide workers with a credible and realistic experience, helping them retain what they have learned by practicing tasks in an immersive 3D virtual environment that simulates the risks of working in a confined space.

Additionally, the integration of voice recognition and an augmented reality (AR) display connected to helmets can provide workers with on-demand training and access to blueprints or manuals to complete their work safely and quickly every time. This is vital for workers operating in a confined space where having a training book or manual on hand may not be possible.

Step 4: Protection

When entering a confined space, workers must have appropriate PPE so that they are protected against the hazards identified during the risk assessment.

Directive 89/656/EEC (on the use of PPE) requires employers to provide workers with appropriate PPE whenever risks cannot be avoided or sufficiently limited by technical means of collective protection or work organization procedures. In general, all PPE used must:

• Be appropriate to the risks involved, without increasing the risk.

• Correspond to the existing conditions in the workplace.

• take into account ergonomic requirements and the health status of the worker.

• Adjust properly to the user after any necessary adjustment.

It is important to remember that high temperature conditions in confined spaces can lead to a dangerous rise in body temperature, which can be aggravated by the use of PPE. Therefore, comfort is as important as quality when selecting PPE for such applications. This is why it is always recommended to rely on a trusted supplier who can help you specify a PPE that is fully suitable for your purpose.

As shown in the technical document 'Knowing the associated risks of working in a confined space', confined spaces present multiple risks so, in most cases, a worker will have to wear different PPE.

In addition to the usual PPE

• Work clothes

• Hull

• Safety footwear / boots

• Gloves

• High visibility vest

Confined space applications require specific protective equipment

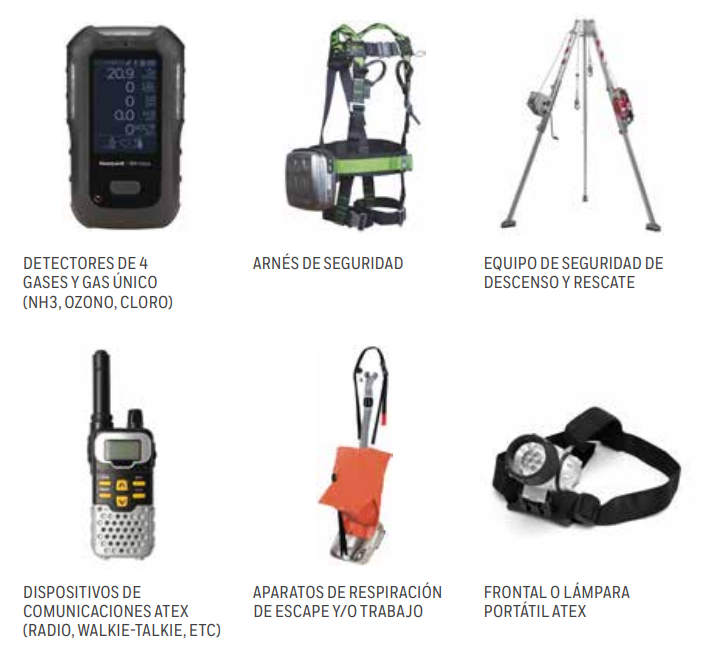

- 4 gas and single gas detectors (NH3, ozone, chlorine)

- Safety harness

- Descent safety equipment

- ATEX communications devices (radio, walkie-talkie, etc.)

- Escape and/or work breathing apparatus

- ATEX front or portable lamp

Confined space applications require specific protective equipment

4-GAS AND SINGLE GAS DETECTORS (NH3, OZONE, CHLORINE) EXHAUST AND/OR WORK BREATHING APPARATUS FRONT SAFETY HARNESS OR ARTEX PORTABLE LAMP

You could also consider using a PPE that integrates biometric monitors to obtain full real-time knowledge of a worker's health status.

Since oxygen deficiency or exposure to toxic gases pose real threats in confined spaces, equipping workers with portable gas detectors is also essential.

Broadly speaking, there are two types of sensors used for gas detection: Generic sensors, which will monitor conditions such as flammability and will react to any gas that forms an explosive mixture with air. Specific gas sensors detect only one chemical component and are used to monitor the level of oxygen, hydrogen sulfide or methane.

Some of the latest gas detectors integrate Bluetooth® technology to connect to an ATEX-certified industrial smartphone and automatically transmit toxic gas readings in real time. In this way, a safety director can, for example, immediately alert a worker operating in a confined space to exit if gas concentration levels are reaching dangerous thresholds.

Step 5: Rescue

Evidence shows that most deaths in confined spaces are suffered by rescuers, so protecting them more effectively is as important as having an effective rescue plan. The first step should always be to adopt an appropriate communication system so that rescuers can rely on clear and accurate information about the environment and the condition of the worker before entering a confined space. One tool that can be considered in this case is motion control technology.

For example, most of the latest portable gas detectors feature man-down alarms that allow for better decisions on how to rescue workers and potentially evacuate others who may be at risk. Additionally, with access to real-time gas readings, rescuers can make informed decisions about things like the type of PPE to wear before entering a confined space. Media must be organized in the confined space before entering, this includes:

• Radio communication

• Oral communication

• Visual communication

• By anchoring

The most practical method of communication is radio communication, although this type of communication may have reception failures in some structures. Additionally, workers have to agree on a communication code in degraded circumstances to use in the event of an accident, which may be coded words, beeps or other signals.

The time spent on rescue needs must also be determined by the victim's condition and environment. The safety of the rescuer is important to the victim, so safety precautions should be taken for the rescue operation, even if it affects the rescue time.

Summary

Working in a confined space involves multiple risks so employers and health and safety professionals need to take many different precautions to protect workers operating in such environments. This technical guide has illustrated that whilst there is legislation in place at EU and national level to ensure that employers meet the minimum safety requirements when a worker has access to a confined space, there are other important steps that can be taken. to ensure that workers and rescuers are properly trained and that they use equipment that is completely suitable for the task