€26.01 (no TAX)

Particulate filter for vapors and gases P2R 2125 3M

Particulate filter for vapours and gases P2R 2125 3M.

Bayonet-type connection suitable for a wide range of reusable semi-masks and complete face masks 3MTM.

It is sold in multiples of 2ud.

€5.20 (no TAX)

The filter 3M 2125 P2R protects against solid and liquid particles. Suitable for half masks 3M 6000 and 7000 series and full masks. Commonly used in the paper and brewing industries.

Particle filters 3M2000 Series™ can be attached to any reusable half or full mask 3M™ with bayonet type connection. They are versatile, small, light and have low breathing resistance.

CHARACTERISTICS

- P2 R and P3 R protection against solid and liquid particles, ozone and nuisance levels of gases and vapors

- They combine protection with comfort and balance

- Small enough to comfortably use with welding helmets

- Lightweight and low breathing resistance

- Bayonet connection fits a wide range of reusable half masks and full masks 3M™

- They attach easily, just screw them in until they click

- Particle filters 3M2000 Series™ can be attached to any reusable half or full mask 3M™ with bayonet type connection. They are versatile, small, light and have low breathing resistance.

- If you need P2 R and P3 R respiratory protection against solid and liquid particles, ozone and nuisance levels of gases and vapors, use particulate filters 3M™ series 2000. To use them, simply choose the type of filter that meets your needs or the requirements of workplace safety policies in hazardous environments. These lightweight filters combine protection with comfort, and are versatile enough to use on our entire range of reusable half masks and full masks. They offer low breathing resistance and good balance when attached to the mask. They also fit comfortably when used with welding helmets, thanks to their flexible and soft structure. They attach quickly and easily and can be used on any reusable mask 3M™ with bayonet type connection.

SPECIFICATIONS

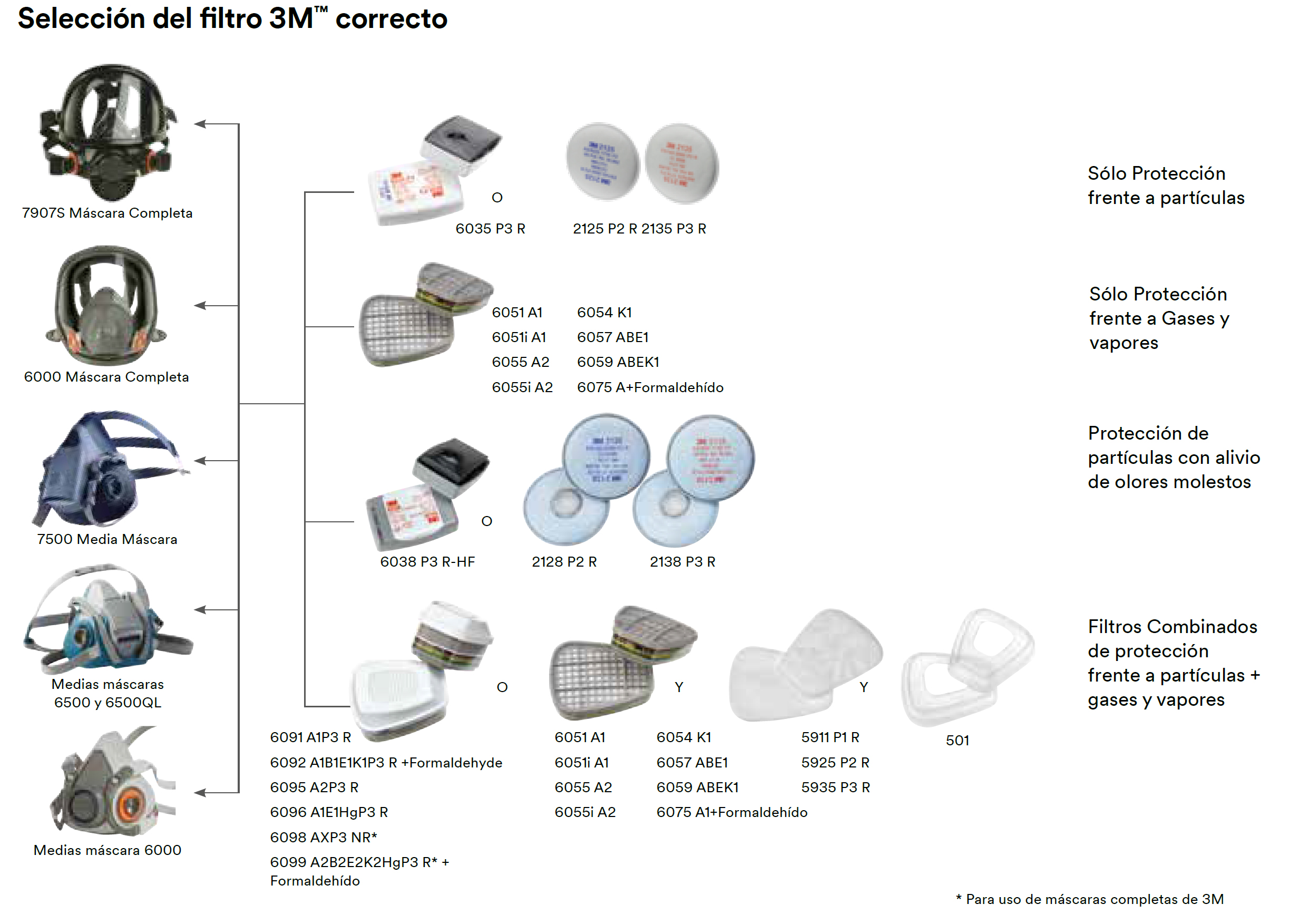

FILTER SELECTION

FILTER DURABILITY

The useful life of filters used in industrial environments depends on factors such as humidity, concentration of contaminant in the environment, temperature, time of use... and must be replaced when resistance to breathing is noticed or the smell or taste of the contaminant is perceived. that is being exposed. Since there are so many work environments, each with its own characteristics, we cannot accurately indicate the durability of the filters.

In general, the useful life of the filters is 5 years from manufacturing, but it is recommended not to use them beyond 6 months from their first use if one of the reasons for their replacement indicated in the previous paragraph has not been met. (The life of an unsealed chemical filter is normally indicated on its label. Once the filter is unsealed, even without using it, it has a maximum duration of 6 months, regardless of the expiration date indicated).

APPLICATIONS

- Suitable for reusable half masks and full masks 3M™ with bayonet connection

- To protect yourself in hazardous environments

ABOUT 3M

3M it has such diverse solutions that have the appropriate response to each need. And if this is not the case, they work together with the client to develop that new way of doing things. This different way of thinking is shown in the studies developed to find the most optimal product for each organization.

@CUSTOMER_NAME@

@AUTHOR_PROFILE@ @COMMENT_ISO_COUNTRY@ @VERIFY_PURCHASE@@COMMENT_TITLE@

@COMMENT_COMMENT@