€26.01 (no TAX)

P3R 5935 filter (2 filters - requires 501 retainer) 3M

Particulate filter P3R 5935 (2 filters - needs retainer 501) 3M.

Suitable for full face masks 3M and Masks 3M of the 6000 series and the 7000 series.

It offers protection P3 R against solid and liquid particles.

€5.58 (no TAX)

Filter P3R 5935 (2 filters - needs retainer 501) 3M. What. Protect against solid and liquid particles P2R.

Timeframe approx. four weeks.

If you need flexible P3 R protection against solid and liquid particles, use the particulate filter 3Mtm 5935, adding particle protection when used with the gas and vapour filter 3Mtm of the 6000 series (requires filter holder 3MTM 501).

Our light particle filters help you work safely in hazardous environments. They are designed to optimise the field of view and can be used with any gas and vapour filter 3Mtm 6000 series and with reusable masks 3Mbayonet type connector.

CHARACTERISTICS

- Requires a filter holder 3M 501

- Suitable for full face masks 3M and Masks 3M of the 6000 series and the 7000 series.

- Protection P3 R against solid and liquid particles

- For use with gas and vapour filters 3Mtm of the 6000 series (requires a 501 retainer)

- They can be used with any half mask or full reusable face mask 3Mtm of bayonet type connection

- Designed to optimize field of view

- They help you work safely in hazardous environments 3Mtm 5935 can be used with 6000 series filters to combine gas and particle protection (together with a 501 filter retainer) or separately (with a 603 filter platform and a 501 filter retainer). Our lightweight filters are designed to optimize the field of view and feature a bayonet-like connection.

SPECIFICATIONS

|

Cartridge or filter type |

P3 R |

APPLICATIONS

For use with reusable masks 3Mtm of bayonet type connection

To work safely in dangerous environments.

Some typical industrial applications for filters are:

- Agriculture

- Construction

- Food industries

- Pharmaceuticals

- Powdered chemicals

- Ceramics from quarries

- Refractory materials

- The carpentry.

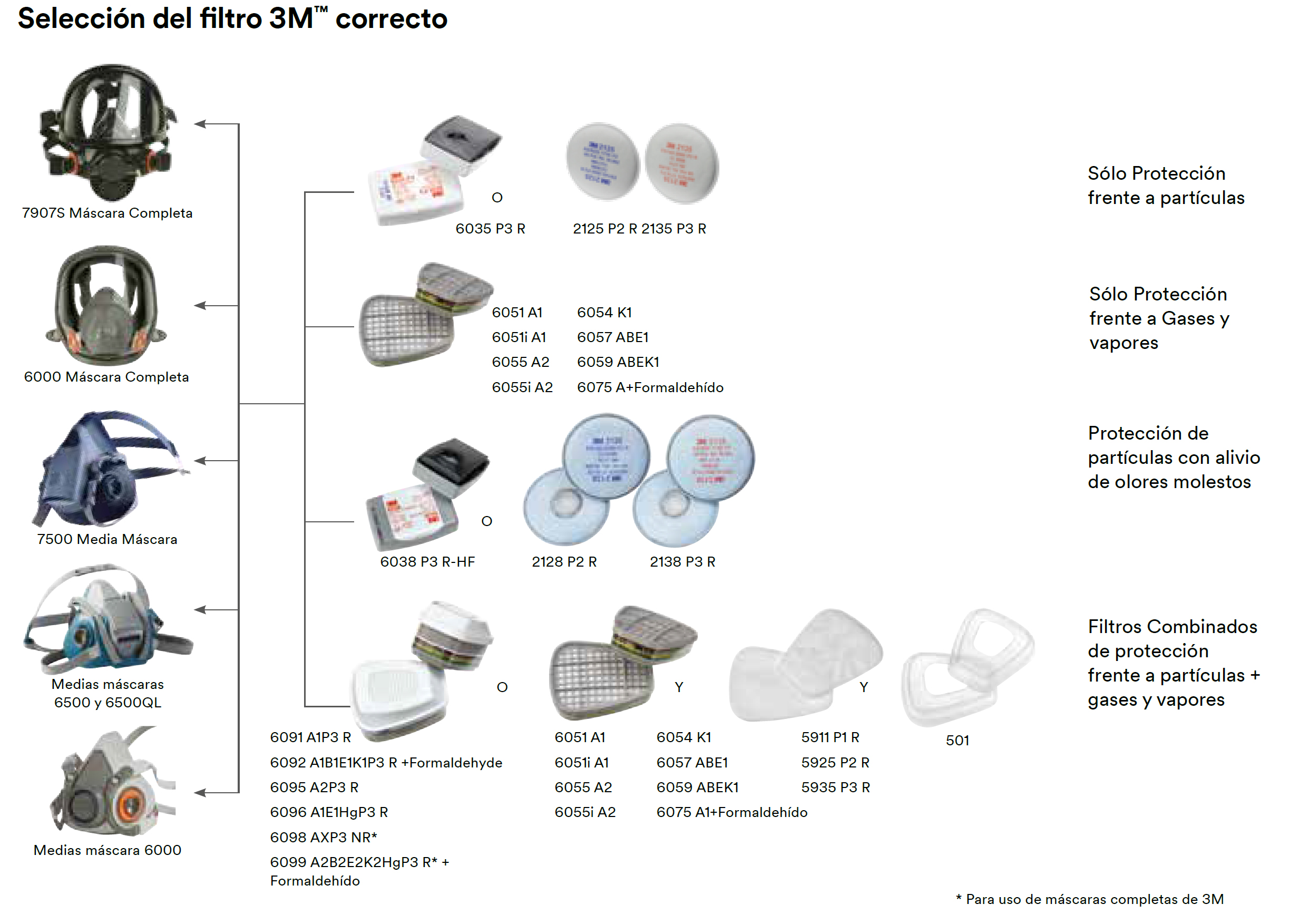

SELECTION OF FILTER

DURABILITY OF FILTERS

Filters used in industrial environments the useful life depends on factors such as humidity, concentration of pollutant in the environment, temperature, time of use ... and must be replaced when you notice resistance to breathing or smell or taste of the pollutant to which you are exposed. Since there are so many work environments, each with its own characteristics, we cannot say precisely how durable the filters are.

Generally the service life of filters is 5 years from manufacture, but it is recommended that they should not be used more than 6 months after their first use if one of the reasons for their replacement mentioned in the previous paragraph has not been met before. (The lifetime of an unsealed chemical filter is normally indicated on the label. Once the filter has been unsealed, it lasts for up to 6 months, regardless of the expiry date indicated on it.).

REGULATORY

EN 143:2000 / A1:2006 Respiratory protective equipment. Particulate filters. Requirements, rehearsals, marked.

ABOUT 3M

3M it has solutions so diverse that they have the right answer for every need. And if not, they work alongside the customer to develop that new way of doing things. This different way of thinking is shown in studies developed to find the most optimal product for each organization.

heading

Ficha Técnica Ficha técnica Filtro P3R 5935 3M download

@CUSTOMER_NAME@

@AUTHOR_PROFILE@ @COMMENT_ISO_COUNTRY@ @VERIFY_PURCHASE@@COMMENT_TITLE@

@COMMENT_COMMENT@